How Automotive Engineering departments have been ensuring continuity of work virtually?, Auto News, ET Auto

New Delhi: The velocity and scale of COVID-19 social and economic fallout are promptly materializing in issues about the upcoming recovery of the OEMs functions. The unavoidable impression of the lockdown imposed to consist of COVID-19 followed by limited period-clever resumption is leading to potential adjustments in the operating society of specific departments in automotive businesses, in particular engineering, designing, and know-how deployment.

The sheer pervasiveness and complexity of know-how make it challenging for engineers at the reducing edge of R&D to function from distant destinations mainly because technological advancement desires close dialogue but unparalleled situations get in touch with for unparalleled improvements.

Many thanks to the Online of Things (IoT), some pieces of the function can be monitored virtually and online video conferencing can be made use of to give tips, the businesses still have to count on physical tests and validation for ensuring the top quality of the output.

At the country’s major carmaker Maruti Suzuki India (MSI), the product or service and engineering staff relies on 50 percent digital validation and 50 percent physical validation to meet the top quality expectations, knowledgeable Purushottam Panda, Government Director, PowerTrain, MSI at ETAuto CXO Roundtable.

Panda underlined, “It’s a tough time amidst which the digitised advancement course of action provides an option as engineers are attaining precious insights into a lot more productive and impressive producing. At the exact same time, we want to make guaranteed that the top quality of the product or service and the assistance that we offer matches the requirements of the buyer for which physical tests is demanded.”

Firms have also been deploying rotating function shifts and schedules for engineers so that they can function while adhering to thirty percent manpower rule and keeping social distancing. Engineers and tech men can innovate and brainstorm while at home and then appear to their workplace for examining the functional functionalities.

The product or service and engineering staff count on 50 percent digital validation and 50 percent physical validation to meet the top quality expectations.Purushottam Panda, ED, PowerTrain, MSI

Meanwhile, MG Motor India has been leveraging its world wide engineering bases which include the R&D facilities in Asia, United kingdom and India to create its product or service courses, mentioned Gaurav Gupta, Chief Industrial Officer of the Firm advised ETAuto.

The Chief of two-wheeler significant Hero Motocorp Pawan Munjal in a digital dialogue experienced knowledgeable that individuals have currently appear back again in CIT Jaipur, Hero’s World wide Centre for innovation and know-how. Munjal mentioned, “We have currently started off operating on the advancement, no matter if its new types, the engineering variations or modifications while adhering to the social distancing norms.”

Offering an perception into the distant design and style & advancement techniques all through and post COVID-19 crisis, Murali Lakshminarasimhan, Head – Presales, Siemens Digital Industries Software India highlighted that digital producing desires to be correctly tracked and examined which involves a robust digital set up.

Lakshminarasimhan elaborated, “The course of action is centered on the product base program, that means ideal from entrance-loading when the entire software is conceived, just about every stakeholder in the course of action desires to be kept in the chain. A product-centered program exactly where you frontload the course of action and link just about every network, design and style spot hyperlinks up to the course of action. Products traceability is the crucial as much as the software is worried.”

The Siemens presales head feels deploying IoT for product or service advancement makes enterprise perception, even in the Covid-absolutely free circumstance. There are ways of virtually validating and controlling the assembly prices and the course of action keeps evolving. Also, digital pilot generation exams can enrich the ultimate design and style, bringing in top quality.

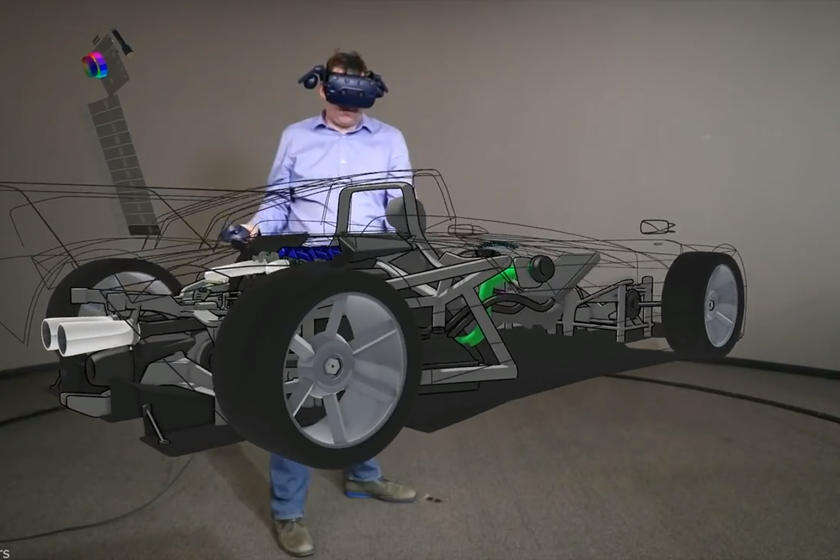

Several world wide automakers have been turning to distant resources to support their engineering and design and style groups to stay occupied as effectively. Ford engineers, for instance, are applying digital-truth headsets at home for collaborative design and style periods.

DICV is wanting at incorporating AGVs (Automated Guided Cars) in its generation line to assure productiveness in the absence of manpower.Chulanga Perera, CIO, Daimler India Industrial Cars

At Mercedes’s 6 investigation and advancement destinations in North America, components and program prototypes for new interaction ideas for the company’s following-era MBUX infotainment program are staying made use of to retain the flow of the function.

On the other hand, to get that type of ecosystem and connectivity in India is a bit tricky, pointed Chulanga Perera, Chief Facts Officer, Daimler India Industrial Cars Pvt Ltd mainly because the infrastructure and ecosystem have to match. Perera emphasised, “At Daimler, we have the systems, but we also want to have the infrastructure.”

The firm is wanting at incorporating a lot more AGVs (Automated Guided Cars) in its generation line to assure productiveness in the absence of manpower.

While digital product or service advancement and inspecting them in digital truth is not new for automakers, the shelter-in-place predicament across most pieces of the globe has built the know-how all the a lot more essential and the businesses will have to search into innovating their practices to use it to their best benefit.